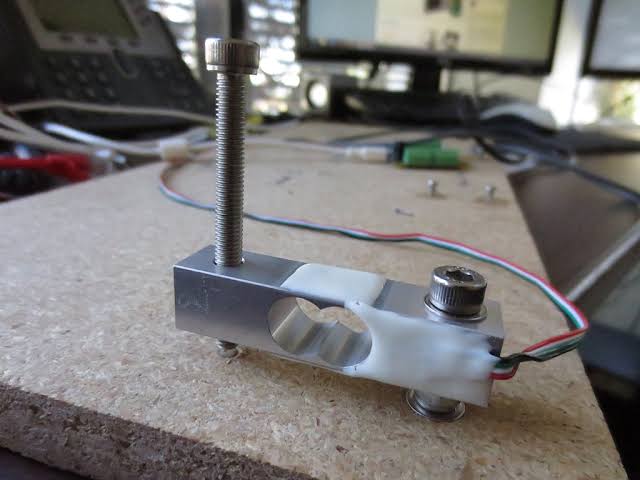

There are number of load cells available which are ideal to be used in a lab or operationally. When you need to transform a force into a measurable output, you need a load cell or a transducer. The strain gauge load cells are used for experimental stress analysis and measuring the resistance to strain electrically. These load cells usually come in handy in industrial applications. If you need precise mechanical balances where intrinsic safety and hygiene is a must, then pneumatic load cells are the best. If operation is located remotely, then hydraulic load cell is the best because it needs no power supply. There are also many other types of load cells like miniature, strain, and beam load cells. Here are more of them discussed below.

Types of load cells

- Platform

These load cells are hermetically sealed and are ideal for applications that need water tightness and very precise accuracy like weighing, industrial food processing, and automatic weighing stations. The resistive load cells made with the bonded foil strain gauges can be accurate, they provide off center load compensation that comes in handy for building scales that are highly accurate even though the objects being measured are kept anywhere on a loading platform.

- S-Type

These load cells get compression output readings. They are meant to deliver best performance in compact and versatile units, tank weighing, suspended loads, and hoppers.

- Canister Style

This can be used for single and multi weighing applications and are water proof and sealed hermetically. The heavy duty design canister load cell sensors have to be sealed environmentally to adjust with the harsh conditions and are ideal for the axial compression applications. The hydrostatically compensated load cells are used for underwater platforms, marine weighing, and on dry docks as well. Every kind of stainless steel build is ideal for marine applications

- Tension/Compression

These are versatile and low profile and are highly accurate for determining the compression and tension forces. The industrial load cell types are made with threaded load connections for measuring tension or compression forces in harsh conditions.

Evaluating the selection

- Measurement Duration: Short-term duration with a Tare, or longer measurement durations without a Tare

- Output Requirements: USB, wireless, digital RS232/RS485, analog mV/V, 0 to 5V, 4 to 20 mA

- Measurement Speeds: 1 Hz, up to 100 Hz, >100 Hz

- Direction of Loading: Tension, compression, or both combined

- Operating Temperature Conditions: Room temperature, outdoor temperature, well-controlled environment for harsh conditions

- Options for Mounting: Fastening sensor to both sides